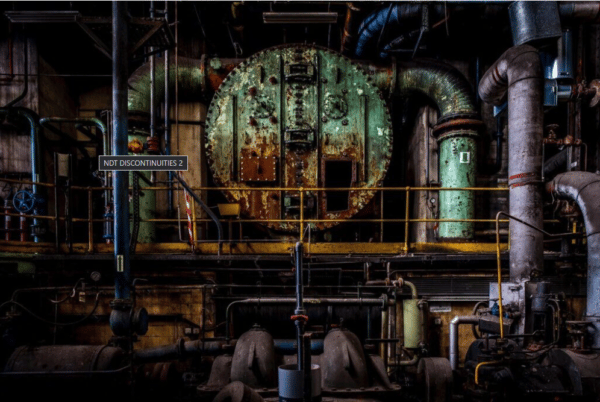

NDT DISCONTINUITIES

NDT DISCONTINUITIES Defectology in NDT deals with the defects that affect all the stages of product realization, starting from raw material to finished product. Discontinuities are imperfections in

Knights Inspection Services offers comprehensive nondestructive testing inspection, integrity, and reconditioning services for tubulars. Our wide range of services help extend the equipment’s life, ensure well integrity, and diagnose failures. Depending on your needs, we provide inspection services at your wellsite, facility or in our yard. A robust inspection program through Knights Inspection Services helps maximize production efficiency and eliminates unwanted nonproductive time.

Our goal at Knights Inspection Services LLC is simple: extraordinary service quality and customer satisfaction. We accomplish this by observing a common set of values and by partnering with organizations that have the finest reputation for quality. In addition to this, our growing success is attributed to our reputation for providing the most knowledgeable inspectors on each job that we are awarded. Clint Knight (Owner) has made a commitment to growing our business slowly and steadily to ensure that any team member assigned to your job is equipped with not only the knowledge needed to assure a quality inspection, but also the integrity to perform at or above the standards of operation set forth by Knights Inspection. We believe that our goals are only attainable with a real commitment from every team member, there are NO shortcuts!

The safety of our employees and customers is our number one concern. Every Knights employee is empowered with the responsibility of Stop Work Authority – the right to halt activity while the hazard is corrected. No operation is so important that it should continue in a manner that permits undue risk to personnel, the public, or property.

We firmly believe that a healthy workforce produces a best-in-class service execution. Our health and wellness programs encourage all our employees to maintain a high fitness for duty and an overall sense of well-being. We strive to maintain top-tier housekeeping and industrial hygiene standards at our customer facilities, ensuring that our employees have a clean and safe place to work every day.

Knights Inspection Services LLC maintains a Quality Management System (QMS) which meets the requirements of organizations that provides manufacturing-related processes and services under a product specification for use in the petroleum and natural gas industry. The elements of Knights Inspection Services QMS are in alignment with ISO 9001 and API Q2 Standards. Knights Inspection is dedicated to strict training programs that allow our service to meet or exceed our customers’ inspection needs. Our inspectors’ ability comes from a dedication to remain highly effective through programs designed by our Quality manager and supported by the entire organization.

NDT DISCONTINUITIES Defectology in NDT deals with the defects that affect all the stages of product realization, starting from raw material to finished product. Discontinuities are imperfections in

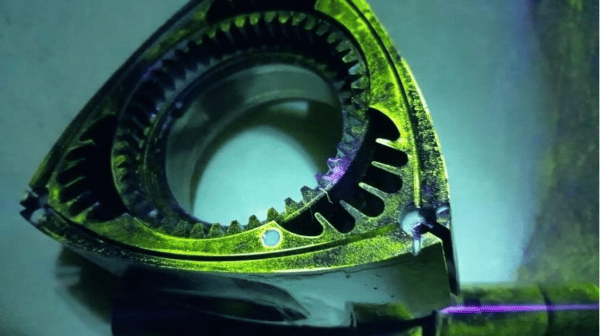

Magnetization Techniques in MT Magnetic particle testing is used to detect surface and shallow subsurface discontinuities such as cracks, laps, seams, cold shuts, and laminations

Phased Array Ultrasonic Testing – PAUT UT – Ultrasonic testing is used to test a variety of both metallic and nonmetallic products, such as welds,