SERVICES

OVERVIEW

Knights Inspection Services (KIS) LLC., provides a full range of nondestructive testing (NDT) for the petroleum and natural gas industry. Our team currently operates throughout the Texas/Louisiana Gulf Cost, West Texas, Oklahoma areas.

KIS provides NDT inspection services for Down Hole Tooling and Structural applications, including Magnetic Particle, Liquid Penetrant, Ultrasonic and Visual Testing. Our team renders services in accordance with industry specified codes/standards or customer specific requirements.

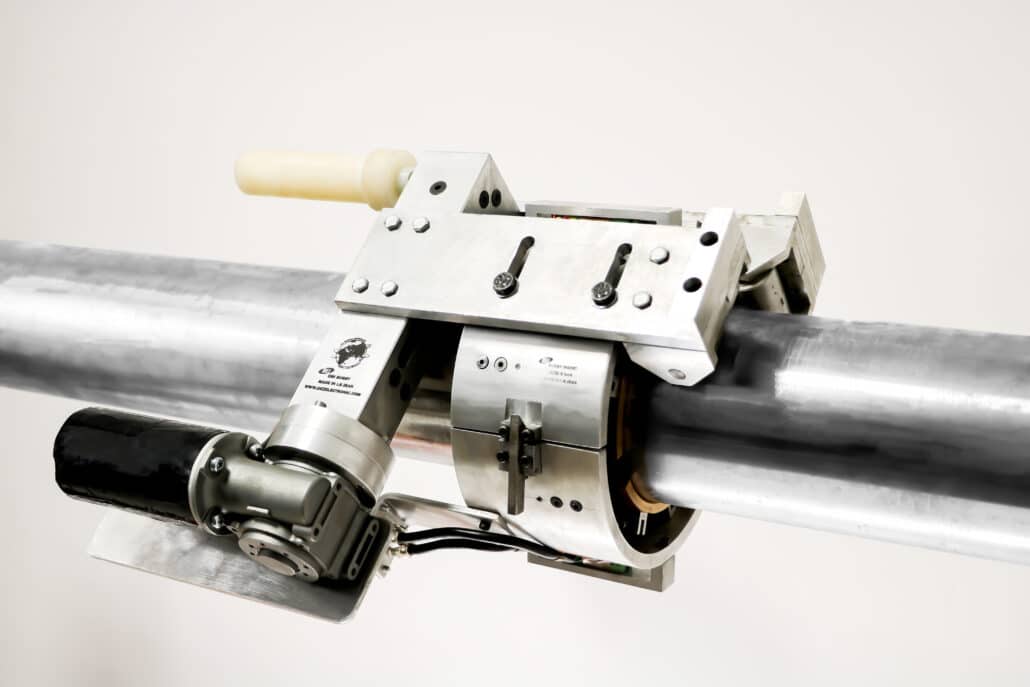

MOBILE EMI UNITS

We have 3 mobile EMI Units available which is equipped with the Artis-3 System. The ARTIS – 3 Portable Inspection System provides high speed state-of-the-art inspection for defects located in used Oil Field Drill Pipe, Tubing, and Casing.

ARTIS-3 units offer the most technologically advanced system available, designed to detect more defect types than any other EMI system in the marketplace, and is the only four-function portable EMI inspection unit available.

TRANSVERSE FLAWS (for holes / cracks / sharp pits)

WALL LOSS TYPE-1 (for corrosion – OD)

WALL LOSS TYPE-2 (for erosion – ID)

FULL-LENGTH WALL THICKNESS MONITORING (thick-thin display for large area gradual wear)

MAGNETIC PARTICLE INSPECTION (MT):

Knights Inspection commonly employs this method on ferromagnetic materials in the oil and gas industry as a preventative measure on downhole tools, structural entities, and some raw materials. The MT method helps detect discontinuities predominantly in a linear form, either at or close to the surface of the material being inspected. Inspectors utilize magnetic fields and many forms of magnetic induction tools to perform a reliable investigation process. Knights’ inspectors apply the correct processes as warranted by the material being inspected when using these wet or dry magnetic techniques.

VISUAL TESTING INSPECTION (VT):

LIQUID PENETRANT INSPECTION (PT):

Liquid penetrant inspection is one of the most commonly used forms of inspection for detecting surface defects on all forms of material. PT can be performed on all forms of material including magnetic or non-magnetic material. However, in the oil and gas industry, the PT method is commonly utilized on non-magnetic materials used in the drilling process. The method is adaptable to a wide range of metals including structural types. Knight’s inspectors are highly trained in the application and implementation to solve inspection needs of our customers.